|

Qingdao Changjie Machine Co., Ltd.

|

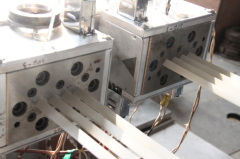

wpc floorboard profile production line

| Price: | 30000.0~60000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.CE

2.high speed

3.high quality

The plastic profile production line is produces the PVC plastic profile specialty production facilities, mainly produces the windows and doors series profile, the plate, the sheet material, micro foam profile, micro foam the decoration plate. The chang jie machinery introduction absorption overseas technology develops the large-scale plastic windows and doors profile equipment, forms a complete set by the cone-shape double screw extruder, has the automaticity to be high, the operating performance is steady, the output is big, efficiency higher merit.

* this series equipment disposition corresponding main engine, the mold and the auxiliary engine, may use in the many kinds of specification profile production.

* suitable raw material: PVC, PP, PE and so on. The special design's screw rod, barrel, guaranteed that the equipment mortgages and the fine plastified effect high speed.

* disposition three dimensional electrically operated vacuum cooling water trough. Mechanical altitude mixture control and lateral adjustment convenience operation, and had guaranteed the product stereotypia is precise.

* the tractor uses the frequency conversion velocity modulation, the wear-resisting hauling caterpillar band or the leather belt guarantee time the hauling high speed and high stable.

* the cutter device and the extruding machine synchronous working, the saw blade positive gearing, may coordinate many kinds of products the cutting requests.

This production line may act according to the different profile cross section and the mold, selects the different specification parallel (conic) the double screw extreuder, and disposes the corresponding vacuum stacker, the tractor, the cutter,tilt stacker and so on supporting facility. The main engine squeezes out the quantity to be possible between each hours 150 kilogram 1450 kilograms optional. The tractor uses our company unique fluctuation technology, the work is steady, the reliability is good, the force of traction is big. The vacuum stereotypia uses enlarges the vortex cooling system specially, is advantageous for cooling to finalize, meets the needs which squeezes out high speed. The cutter traveling speed and the pulling speed maintain synchronizations, the complete movement uses imports the PLC computer control, the rational design, the movement is steady, but automatic fixed-length cutting, and provides the dust reclamation plant. According to the different mold, finalizes Taiwan to be possible to select 4 meter, 6 meter, 8 meter, 11 meters and so on specifications. Disposes the parallel double screw extruder, is suitable specially for the profile squeezes out high speed.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Profile Production Line

Pvc Profile Production Line

Plastic Profile Production Line

Wpc Profile

Wpc Profile Extrusion

Production Line

More>>