|

Qingdao Changjie Machine Co., Ltd.

|

wood plastic composite door frame extrusion line

| Price: | 30000.0~50000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

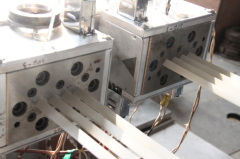

Wood plastic profile machine

1.high effective screw extruder

2.for every size profile

3.good quality

4.steady performance

wood plastic composite door frame machine

The WPC profiles extrusion line is specializing in producing wood-plastic profiles including doors and windows profiles, decorative plates, tiny foaming profiles and decorative plates. By Absorbing advanced technology from abroad, our company developed the large plastic profile extrusion line, which is equipped with conical double-screw extruder, and it possesses the advantages of high degree automation, stable performance, high output and efficiency, etc.

This production line uses PE/PP/PVC powder as material to produce various sorts of the mentioned plastic profiles as profiles for doors and windows, decorative profiles, etc. As the extrusion line is optimumly designed by referring to the latest overseas technology, it bears the features of even plasticization, low cutting rate, high output, and long lifespan, etc. And it composes conical double-screw extruder, vacuum sizing platform, tractor, cutting and film coating machine and material stirring bracket,etc. The main machine is run by alternating current frequency controller or direct current controllable silicon. The temperature controlling instrument is introduced from abroad. In addition, the vacuum pump and traction engine of the auxiliary machines are quality products which can be maintained easily. If change certain screw and mould, this profiles extrusion line can directly extrude foaming profiles, and the effect is much better than that of single-screw.

To match with different moulds, the shape-fixing platform of 4m, 6m, 8m or 11m, etc. can be chosen accordingly. The main machine with parallel double-screw is especially suitable for high-speed extrusion of various kinds of profiles.

This production line uses PE/PP/PVC powder as material to produce various sorts of the mentioned plastic profiles as profiles for doors and windows, decorative profiles, etc. As the extrusion line is optimumly designed by referring to the latest overseas technology, it bears the features of even plasticization, low cutting rate, high output, and long lifespan, etc. And it composes conical double-screw extruder, vacuum sizing platform, tractor, cutting and film coating machine and material stirring bracket,etc. The main machine is run by alternating current frequency controller or direct current controllable silicon. The temperature controlling instrument is introduced from abroad. In addition, the vacuum pump and traction engine of the auxiliary machines are quality products which can be maintained easily. If change certain screw and mould, this profiles extrusion line can directly extrude foaming profiles, and the effect is much better than that of single-screw.

To match with different moulds, the shape-fixing platform of 4m, 6m, 8m or 11m, etc. can be chosen accordingly. The main machine with parallel double-screw is especially suitable for high-speed extrusion of various kinds of profiles.

The component of production line

Item | Name | Model | Qty | Details |

1.1 | Twin screw extruder | SJMS65-132 | 1Unit | With automatic spring loader |

1.2 | Vacuum calibrating platform | SZD-6000 | 1Unit | |

1.3 | Caterpillar haul off | SLQ-240 | 1Unit | |

1.4 | Cutting unit | SQG-240 | 1Unit | |

1.5 | Tilt stacker | SFZ-6000 | 1Unit |

2, Description

Item | Description | Parameters |

2.1 | Material | PVC and wood powder grain (after granulation) |

2.2 | Production line speed | 0.5-1.5m/min |

2.3 | Max. output | 240kg/h |

2.4 | Overall dimensions | 20m×3.5m×3m (L×W×H) |

2.5 | Weight(Approx) | 12T |

2.6 | Total installed power | 125kw |

2.7 | Actual energy consumption power | 85kw |

2.8 | Gas consumption | 0.4m3/min |

2.9 | Air pressure | 0.6mpa |

2.10 | Water circulating device | 0.5m3/min |

2.11 | Electric condition | 380V/3P/50Hz |

2.12 | Water supply | Water used for industry, no impurities, by filtrating, water pressure: 0.4mpa water temperature14~25°C |

2.13 | Work environment temperature | 0-40°C |

we will supply machinery with good quality and service.Looking forward to your inquiry.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Wood Plastic Extrusion Line

Composite Wood Door

Solid Wood Composite Door

Aluminum Wood Composite Door

Plastic Pipe Extrusion Line

Plastic Profile Extrusion Line

More>>